↧

Drug Patents International

↧

Janssen seeks FDA approval for Yondelis (Trabectedin) drug to treat advanced STS

Janssen seeks FDA approval for Yondelis (Trabectedin) drug to treat advanced STS

ET-743, Yondelis (trabectedin)

Trabectedin, Ecteinascidin 743, NSC-684766, ET-743, Yondelis, ID0YZQ2TCP

cas 114899-77-3

(-)-(1’R,6R,6aR,7R,13S,14S,16R)-5-Acetoxy-6′,8,14-trihydroxy-7′,9-dimethoxy-4,10,23-trimethyl-1′,2′,3′,4′,6a,7,12,13,14,16-decahydro-6H-spiro[6,16-(epithiopropanoxymethano)-7,13-epimino-1,3-dioxolo[7,8]isoquino[3,2-b][3]benzazocine-20,1′-isoquinolin]-19-one

Janssen seeks FDA approval for Yondelis drug to treat advanced STS

Janssen Research & Development is seeking approval from US Food and Drug Administration (FDA) for its Yondelis (trabectedin) to treat patients with advanced soft tissue sarcoma (STS).

Trabectedin, also referred as ET-743 during its development, is a marine derived antitumoral agent discovered in the Carribean tunicate _Ecteinascidia turbinata_ and now produced synthetically. Trabectedin has a unique mechanism of action. It binds to the minor groove of DNA interfering with cell division and genetic transcription processes and DNA repair machinery.It is approved for use in Europe, Russia and South Korea for the treatment of advanced soft tissue sarcoma. It is also undergoing clinical trials for the treatment of breast, prostate, and paediatric sarcomas. The European Commission and the U.S. Food and Drug Administration (FDA) have granted orphan drug status to trabectedin for soft tissue sarcomas and ovarian cancer.

Trabectedin (also known as ecteinascidin 743 or ET-743) is an anti-tumor drug. It is sold byZeltia and Johnson and Johnson under the brand name Yondelis. It is approved for use in Europe, Russia and South Korea for the treatment of advanced soft tissue sarcoma. It is also undergoing clinical trials for the treatment of breast, prostate, and paediatric sarcomas. The European Commission and the U.S. Food and Drug Administration (FDA) have grantedorphan drug status to trabectedin for soft tissue sarcomas and ovarian cancer.

Discovery and development

The ecteinascidins (herein abbreviated ETs) are exceedingly potent antitumor agents isolated from the marine tunicate Ecteinascidia turbinata. Several ecteinascidins have been reported previously in the patent and scientific literature. See, for example U.S. Pat. No. 5,089,273, which describes novel compounds of matter extracted from the tropical marine invertebrate Ecteinascidia turbinata, and designated therein as ecteinascidins 729, 743, 745, 759A, 759B and 770. These compounds are useful as antibacterial and/or antitumor agents in mammals. U.S. Pat. No. 5,478,932 describes other novel ecteinascidins isolated from the Caribbean tunicate Ecteinascidia turbinata, which provide in vivo antitumor activity against P388 lymphoma, B16 melanoma, M5076 ovarian sarcoma, Lewis lung carcinoma, and the LX- I human lung and MX- 1 human mammary carcinoma xenografts.

One of the ETs, ecteinascidin 743 (ET-743), is a tetrahydroisoquinoline alkaloid with considerable in vitro and in vivo antitumor activity in murine and human tumors, and potent antineoplastic activity against a variety of human tumor xenografts grown in athymic mice, including melanoma, ovarian and breast carcinoma.

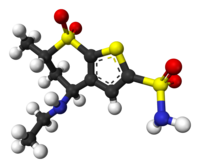

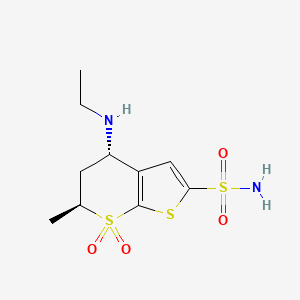

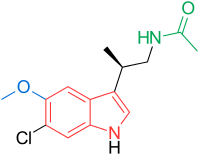

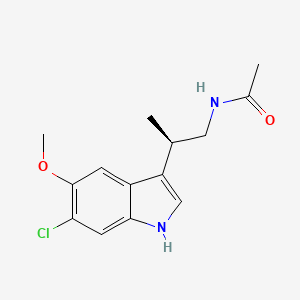

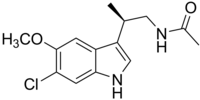

ET-743 is a natural compound with the following structure:

ET-743 is also known with the generic name trabectedin and the trademark Yondelis®, and it is currently approved in Europe for the treatment of soft tissue sarcoma. The clinical development of trabectedin continues in phase 11/ III clinical trials in breast, ovarian and prostate cancer. A clinical development program of ET-743 in cancer patients was started with phase I studies investigating 1- hour, 3-hour, 24-hour, and 72-hour intravenous infusion schedules and a 1 hour daily x 5 (dx5) schedule. Promising responses were observed in patients with sarcoma, breast and ovarian carcinoma.

Therefore this new drug is currently under intense investigation in several phase 11/ III clinical trials in cancer patients with a variety of neoplastic diseases. Further information regarding the dosage, schedules, and administration of ET-743 for the treatment of cancer in the human body, either given alone or in combination is provided in WO 00/69441 , WO 02/36135, WO 03/39571 , WO 2004/ 105761 , WO 2005/039584, WO 2005/049031 , WO 2005/049030, WO 2005/049029, WO 2006/046080, WO 2006/005602, and PCT/US07/98727, which are incorporated by reference herein in their entirety.

A review of ET-743, its chemistry, mechanism of action and preclinical and clinical development can be found in Kesteren, Ch.

Van et al., Anti-Cancer Drugs, 2003, 14 (7), 487-502: “ET-743 (trabectedin, ET-743): the development of an anticancer agent of marine origin”, and references therein.

During the past 30 years medical oncologists have focused to optimise the outcome of cancer patients and it is just now that the new technologies available are allowing to investigate polymorphisms, gene expression levels and gene mutations aimed to predict the impact of a given therapy in different groups of cancer patients to tailor chemotherapy. Representative examples include the relationship between the Thymidylate Synthase (TS) mRNA expression and the response and the survival with antifolates, beta tubulin III mRNA levels and response to tubulin interacting agents, PTEN gene methylation and resistance to CPT- I l and, STAT3 over expression and resistance to Epidermal Growth Factor (EGF) interacting agents.

A molecular observation of potential clinical impact relates to the paradoxical relation between the efficiency of the Nucleotide Excision Repair (NER) pathway and the cytotoxicity of ET-743. In fact, tumour cells that are efficient in this DNA repair pathway appear to be more sensitive to ET-743. This evidence is in contrast with the pattern noted with platin based therapeutic regimens which are highly dependent on the lack of activity of this repair pathway (ie. an increase in ERCCl expression has been associated to clinical resistance to platinum-based anti-cancer therapy).

There are evidences on the key role of NER pathways on the cytotoxicity of ET-743 in cell lines. ET-743 binds to G residues in the minor groove of DNA forming adducts that distort the DNA helix structure and they are recognised by NER mechanisms (Pourquier, P. et al., 2001 , Proceedings of the American Association for Cancer Research Annual Meeting, Vol. 42, pp. 556. 92nd Annual Meeting of the American Association for Cancer Research. New Orleans, LA, USA. March 24-28, 2001. ISSN: 0197-016X). Takebayasi et al. (Nature Medicine, 2001 , 7(8), 961-966) have proposed that the presence of these DNA adducts in transcribed genes, blocks the Transcription Coupled NER (TC-NER) system by stalling the cleavage intermediates and producing lethal Single Strand Breaks (SSBs). It is known from Grazziotin et al (Proc.Natl.Acad.Sic.USA, 104: 13062- 13067) that the DNA adducts formed by exposure to ET-743 are transformed into double strand DNA breaks.

The fact that NER mediates ET-743 ‘s cytotoxicity has also been found in the yeast Saccharomyces cerevisae by Grazziotin et al. (Biochemical Pharmacology, 2005, 70, 59-69) and in the yeast Schizosaccharomyces pombe by Herrero et al. (Cancer Res. 2006, 66(16), 8155-8162).

In addition, Bueren et al. (Proceedings AACR Annual Meeting 2007, Abstract no. 1965) have been shown that ET-743 induces double-strand breaks in the DNA in early S phase that are detected and repaired by the Homologous Recombination Repair (HRR) pathway. In addition, Erba et al (Eur. J. Cancer, 2001 , 37(1), 97- 105) and Bueren et al (Proceedings AACR Annual Meeting 2007, Abstract no. 1965) have shown that inactivation/ mutations of genes related to the Double Strand Break detection such as DNA-PK, ATM and ATR and of genes related to Homologous Recombination Repair pathway, such as Fanconi Anemia genes, BRCAl , BRCA2 and RAD51 make cells more sensitive to trabectedin. Such unique finding is the opposite to the pattern with conventional DNA interacting agents, like in the case of microtubule poisons such as taxanes and vinorelbine.

Finally, pharmacogenomic studies prior have demonstrated that increased expression of the NER genes ERCCl and XPD in the tumor tissue does not impact the outcome of patients treated with

ET-743. However, the low expression of BRCAl in the tumor tissue is correlated with a better outcome in cancer patents treated with

ET-743. Further information can be found in WO 2006/005602, which is incorporated by reference herein in its entirety.

Three rare, autosomal recessive inherited human disorders are associated with impaired NER activity: xeroderma pigmentosum (XP), Cockayne Syndrome (CS), and trichothiodystrophy (Bootsma et al. The Genetic Basis of Human Cancer. McGraw-Hill, 1998, 245- 274). XP patients exhibit extreme sensitivity to sunlight, resulting in a high incidence of skin cancers (Kraemer et al. Arch. Dermatol. 123, 241-250, and Arch. Dermatol. 130, 1018- 1021). About 20% of XP patients also develop neurologic abnormalities in addition to their skin problems. These clinical findings are associated with cellular defects, including hypersensitivity to killing and mutagenic effects of UV, and inability of XP cells to repair UV-induced DNA damage (van Steeg et al. MoI. Med. Today, 1999, 5, 86-94).

Seven different NER genes, which correct seven distinct genetic XP complementation groups (XPA-XPG), have been identified (Bootsma et al. The Genetic Basis of Human Cancer. McGraw-Hill, 1998, 245-274). The human gene responsible for XP group G was identified as ERCC5 (Mudgett et al. Genomics, 1990, 8, 623-633; O’Donovan et al. Nature, 1993, 363, 185- 188; and Nouspikel et al. Hum. MoI. Genet. 1994, 3, 963-967). The XPG gene codes for a structure-specific endonuclease that cleaves damaged DNA ~5 nt 3′ to the site of the lesion and is also required non-enzymatically for subsequent 5′ incision by the XPF/ ERCCl heterodimer during the NER process (Aboussekhra et al. Cell, 1995, 80, 859-868; Mu et al. J. Biol. Chem. 1996, 271 , 8285-8294; and Wakasugi et al. J. Biol. Chem. 1997, 272, 16030- 16034). There is also evidence suggesting that XPG is also involved in transcription-coupled repair of oxidative DNA lesions (Le Page et al. Cell, 101 , 159- 171).

Takebayashi et al. (Cancer Lett., 2001 , 174: 1 15- 125) have observed an increase in heterozygosity loss and microsatellite instability in a substantial percentage of samples of ovarian, lung and colon carcinoma. Le Moirvan et al, (Int.J. Cancer, 2006,1 19: 1732- 1735) have described the presence of polymorphisms in the XPG gene in sarcoma patients. It is also known from Takebayashi et al. (Proceedings of the American Association forCancer Research Annual Meeting, March, 2001 , Vol. 42, pp. 813.92nd Annual Meeting of the American Association for Cancer

Research. New Orleans, LA, USA. March 24-28, 2001) that cells deficient in the NER system are resistant to treatment with ET-743 (Zewail-Foote, M. et al., 2001 , Chemistry and Biology, 8: 1033- 1049 and Damia, G. et al., 2001 , Symposium AACR NCI EORTC) and that the antiproliferative effects of ET-743 require a functional XPG gene.

Since cancer is a leading cause of death in animals and humans, several efforts have been and are still being undertaken in order to obtain an antitumor therapy active and safe to be administered to patients suffering from a cancer. Accordingly, there is a need for providing additional antitumor therapies that are useful in the treatment of cancer.

Trabectedin is a tetrahydroisoquinoline, a novel marine-derived antitumor agent isolated from the colonial tunicate Ecteinascidia turbinate. The drug binds to the minor groove of the DNA, bending the DNA towards the major groove, blocking the activation of genes in a unique way via several pathways, including selective inhibition of the expression of key genes (including oncogenes) involved in cell growth and drug resistance, inhibition of genetic repair pathways and inhibition of cell cycle progression leading to p53-independent programmed cell death.

In July 2003, the European Committee of Proprietary Medicinal Products (CPMP) recommended against granting marketing authorization to trabectedin for soft tissue sarcoma. PharmaMar appealed the decision in September 2003. Later that year, the CPMP rejected the company’s appeal. In 2006, the company filed another regulatory application for this indication and, finally, in 2007, a positive opinion was received in the E.U. for the treatment of metastatic soft tissue sarcoma. First commercialization of the product in the E.U. took place in October 2007 in the U.K. and Germany.

The compound is also available in several other countries. In 2008, the compound was filed for approval in the U.S. and the E.U. for the treatment of relapsed advanced ovarian cancer in combination with liposomal doxorubicin, and in 2009 approval was received in both countries. Trabectedin is available in several European countries, including the U.K. and Germany. Also in 2009 the drug candidate was approved in Philippines for the ovarian cancer indication.

The compound had been in phase II development by Johnson & Johnson for the treatment of prostate cancer; however, no recent development has been reported for this research. PharmaMar is evaluating the compound in phase II trials for the treatment of breast cancer. Additional early clinical trials are ongoing at the National Cancer Institute (NCI) to evaluate trabectedin for potential use in the treatment of advanced, persistent or recurrent uterine leiomyosarcomas and solid tumors.

In 2011, a regulatory application that had been filed in the U.S. seeking approval for the treatment of relapsed advanced disease in combination with liposomal doxorubicin was withdrawn by the company based on the FDA’s recommendation that an additional phase III study be conducted to obtain approval. In 2014, Janssen Research & Development, LLC submitted an NDA for trabectedin to the FDA for the treatment of patients with advanced soft tissue sarcoma (STS), including liposarcoma and leiomyosarcoma subtypes, who have received prior chemotherapy including an anthracycline.

Trabectedin was developed by PharmaMar, a subsidiary of Zeltia. The drug was being codeveloped and comarketed in partnership with Ortho Biotech, a subsidiary of Johnson & Johnson pursuant to an agreement signed in 2001. However, in 2008 the license agreement between the two companies was terminated.

The compound was granted orphan drug designation for the treatment of soft tissue sarcoma and for the treatment of ovarian cancer by the FDA and the EMEA. In 2011, orphan drug designation was granted in Japan for the treatment of malignant soft tissue tumor accompanied with chromosomal translocation. In 2009, the product was licensed to Taiho by PharmaMar in Japan for the treatment of cancer.

During the 1950s and 1960s, the National Cancer Institute carried out a wide ranging program of screening plant and marine organism material. As part of that program extract from the sea squirt Ecteinascidia turbinata was found to have anticancer activity in 1969.[1]Separation and characterisation of the active molecules had to wait many years for the development of sufficiently sensitive techniques, and the structure of one of them, Ecteinascidin 743, was determined by KL Rinehart at the University of Illinois in 1984.[2]Rinehart had collected his sea squirts by scuba diving in the reefs of the West Indies.[3]

Recently, the biosynthetic pathway responsible for producing the drug, has been determined to come from Candidatus Endoecteinascidia frumentensis, a microbial symbiont of the tunicate.[4] The Spanish company PharmaMar licensed the compound from the University of Illinois before 1994 and attempted to farm the sea squirt with limited success.[3]

Yields from the sea squirt are extremely low – it takes 1 tonne of animals to isolate 1 gram of trabectedin – and about 5 grams were believed to be needed for a clinical trial[5] so Rinehart asked the Harvard chemist E. J. Corey to search for a synthetic method of preparation. His group developed such a method and published it in 1996.[6] This was later followed by a simpler and more tractable method which was patented by Harvard and subsequently licensed to PharmaMar.[3] The current supply is based on a semisynthetic process developed by PharmaMar starting from Safracin B, an antibiotic obtained by fermentation of the bacterium Pseudomonas fluorescens.[7] PharmaMar have entered into an agreement with Johnson and Johnson to market the compound outside Europe.

Trabectedin was first dosed in humans in 1996.In 2007, the EMEA gave authorisation for the marketing of trabectedin, under the trade name Yondelis, for the treatment of patients with advanced soft tissue sarcoma, after failure of anthracyclines and ifosfamide, or who are unsuited to receive these agents. The agency’s evaluating committee, the CHMP observed that trabectedin had not been evaluated in an adequately designed and analyzed randomized trial against current best care, and that the clinical efficacy data was mainly based on patients with liposarcoma and leiomyosarcoma. However the pivotal study did show a significant difference between two different trabectedin treatment regimens, and due to the rarity of the disease the CHMP considered that marketing authorisation could be granted under exceptional circumstances.[8] As part of the approval PharmaMar agreed to conduct a further trial to identify whether any specific chromosomal translocations could be used to predict responsiveness to trabectedin.[9] Trabectedin is also approved in South Korea[10] and Russia.

In 2008 the submission was announced of a registration dossier to the European Medicines Agency (EMEA) and the FDA for Yondelis when administered in combination with pegylated liposomal doxorubicin (Doxil, Caelyx) for the treatment of women with relapsed ovarian cancer. In 2011, Johnson&Johnson voluntarily withdrew the submission in the United States following a request by the FDA for an additional Phase III study to be done in support of the submission.[11]

Trabectedin is also in phase II trials for prostate, breast and paediatric cancers.[12]

Structure

Trabectedin is composed of 3 tetrahydroisoquinoline moieties, 8 rings including one 10-membered heteocyclic ring containing a cysteine residue, and 7 chiral centers.

Biosynthesis

The biosynthesis of Trabectedin in Candidatus Endoecteinascidia frumentensis starts with a fatty acid loading onto the acyl-ligase domain of the EtuA3 module. A cysteine and glycine are then loaded as canonical NRPS amino acids. A tyrosine residue is modified by the enzymes EtuH, EtuM1, and EtuM2 to add a hydroxyl at the meta position of the phenol, and adding two methyl groups at the para-hydroxyl and the meta carbon position. This modified tyrosine reacts with the original substrate via a Pictet-Spangler reaction, where the amine group is converted to an imine by deprotonation, then attacks the free aldehyde to form a carbocation that is quenched by electrons from the methyl-phenol ring. This is done in the EtuA2 T-domain. This reaction is done a second time to yeid a dimer of modified tyrosine residues that have been further cyclized via Pictet-spangler reaction, yielding a bicyclic ring moiety. The EtuO and EtuF3 enzymes continue to post-translationally modify the molecule, adding several functional groups and making a sulfide bridge between the original cysteine residue and the beta-carbon of the first tyrosine to form ET-583, ET-597, ET-596, and ET-594 which have been previously isolated.[4] A third o-methylated tyrosine is added and cyclized via Pictet-Spangler to yield the final product.[4]

Synthesis

The total synthesis by E.J. Corey used this proposed biosynthesis to guide their synthetic strategy. The synthesis uses such reactions as the Mannich reaction, Pictet-Spengler reaction, the Curtius rearrangement, and chiral rhodium-based diphosphine-catalyzedenantioselective hydrogenation. A separate synthetic process also involved the Ugi reaction to assist in the formation of the pentacyclic core. This reaction was unprecedented for using such a one pot multi-component reaction in the synthesis of such a complex molecule.

Org Lett 2000,2(7),993

The previously reported synthesis of 139221 (scheme 13922101a) has been investigated in order to find a more efficient, reproducible and economical route to work in the mutikilogram scale. Herein it is reported a new process which is simpler and proceeds with an overall yield of 54% (the original process, 35%). The condensation of intermediate aminolactone (I) (scheme 13922101a, intermediate (VII)) with acid (XLII) (the acid derived from scheme 13922101a, intermediate ester (IX)) by means of 2-chloro-1,3-dimethylimidazolidinium hexafluorophosphate (CIP), and 1-hydroxy-7-azabenzotriazole (HOAt) in THF/dichloromethane gives the coupling product (XLIII), which is allylated with allyl bromide (XLIV) and Cs2CO3 in DMF yielding the allyl ether (XLV). The reduction of the lactone group of (XLV) with LiAlH2(OEt)2 in ethyl ether affords the lactol (XLVI), which is desilylated with KF in methanol to provide the phenolic compound (XLVII). The opening of the lactol ring of (XLVII) with simultaneous cyclization by means of Tf-OH in water/trifluoroethanol gives the hexacyclic intermediate (XLVIII), which is finally reductocondensed with KCN by means of LiAlH2(OEt)2 in THF to furnish the previously reported pentacyclic intermediate (XI) (scheme 13922101a, intermediate (XI)).

……………………………………………

Reaction of cyanosafracin B (I) with Boc2O in ethanol gives the amino-protected compound (II), which is treated with methoxymethyl bromide (MOM-Br), DIEA and DMAP in acetonitrile yielding the O-protected compound (III). The demethylation of (III) with NaOH in methanol affords the hydroxyquinone (IV), which is reduced with H2 over Pd/C and cyclized with bromochloromethane and Cs2CO3 in hot DMF to provide compound (V). Reaction of (V) with allyl bromide (VI) and Cs2CO3 in DMF gives the allyl ether (VII), which first is treated with TFA, phenyl isothiocyanate and HCl to yield the primary amine (VIII) and then protected at the free NH2 group with Troc-Cl and pyridine, to afford the amino protected compound (IX).Org Lett 2000,2(16),2545

……………………………….

Reaction of (IX) with MOM-Br and DIEA as before affords the ether (X), which is treated with Zn/HOAc in order to regenerate the primary amino group giving (XI). The reaction of (XI) with NaNO2 and HOAc eliminates the NH2 group, affording the primary alcohol (XII), which is esterified with the protected (S)-cysteine (XIII) by means of EDC and DMAP in dichloromethane furnishing the cysteine ester (XIV). Reaction of (XIV) with Bu3SnH and PdCl2(PPh3)2, followed by oxidation with (PhSeO)2O in dichloromethane gives the hydroxyketone (XV), which is cyclized with Tf2O and Ac2O yielding the heptacyclic compound (XVI). Elimination of the MOM protecting group with TMSCl and NaI in CH3CN/CH2Cl2 affords the phenolic compound (XVII).

…………………….

Intermediate (XVII) by a treatment with Zn and HOAc eliminates the Troc protecting group, giving the primary amine (XVIII). This compound by treatment with 4-formyl-1-methylpyridinium iodide (NMPC), DBU and oxalic acid in order to convert the nitrile group into an alcohol, provides compund (XIX), which is finally cyclized with 2-(3-hydroxy-4-methoxyphenyl)ethylamine (XX) by means of SiO2 / EtOH, followed treatment with and AgNO3 in acetonitrile/water.

……………………….

The reaction of cyanosafracin B (I) with Boc2O in ethanol gives the amino protected compound (II), which is treated with Mom-Br, DIEA and DMAP in acetonitrile yielding the O-protected compound (III). The demethylation of (III) with NaOH in methanol affords the hydroxyquinone (IV), which is reduced with H2 over Pd/C and cyclized with bromochloromethane and Cs2CO3 in hot DMF providing the methylenedioxy compound (V). The reaction of (V) with acetyl chloride and pyridine in dichloromethane gives the acetate (VI), which is treated with TFA, phenyl isothiocyanate and HCl yielding the primary amine (VII). Finally, this compound is treated with phthalic anhydride (VIII) and CDI in dichloromethane to afford the target phthalimide (phthalascidin Pt-650)

………………………………

Org. Lett., 2000, 2 (7), pp 993–996

DOI: 10.1021/ol0056729

Org. Lett., 2000, 2 (7), pp 993–996

DOI: 10.1021/ol0056729

…………………………

Enantioselective Total Synthesis of Ecteinascidin 743

Department of Chemistry, Harvard University Cambridge, Massachusetts 02138

J. Am. Chem. Soc., 1996, 118 (38), pp 9202–9203

DOI: 10.1021/ja962480t

……………………………….

Ecteinascidins are a group of marine alkaloid having antineoplasticity which is isolated from the extracted products from the marine tunicate habitat of the Caribbean sea by a very small amount. Arming the ecteinascidins, Et 743 has a very strong antineoplastic activity, studies to put it into practical use as a carcinostatic agent are limited, and the phase II clinical tests are now being carried out in ten countries in Europe and America. It is known that Et 743 has an effect of depressing the proliferation of cancer cells by 10 to 100 times more potent than (IC50=0.1-1 nM) Toxol, Camptotesin, Adriamycin or Mitomycin which are currently used carcinostatic agents.

From the background mentioned above, various studies for synthesis were carried out; however, the complete synthesis was only reported by Prof. E. J. Corey of Harvard University in the U.S.A. (J. Am. Chem. Soc. 1996, 118, 9202-9203, reference document A).

In the process of the total synthesis disclosed in Document A (refer to page 9202), the main feature of the process is that Et 743 is synthesized from the analogous compound to the compound represented by general formula 1 of the present invention via intermediates 4 and 8. That is, according to said process, the C4 site of ring B (regarding the location of rings, and the sites of atoms comprising the 6 membered ring, refer to general formula 1), which composes a 6 membered ring, is formed from the intermediate 4 at the first step. Since the atom C4 composing the ring B of the 6-membered ring H, which lacks reactivity, is bonded, it becomes necessary to perform an oxidation reaction at the C4 site on the B ring. This oxidation reaction is not effective and is carried out under harsh conditions; therefore production on an industrial scale is difficult, and also the yield is not good. Further, since the atom N12 site of the synthesized intermediate is substituted by an alkyl group which lacks reactivity, in this case substituted by a methyl group, it is not suited to the synthesis of various compounds. Although total synthesis was reported, the supplying source of Et 743 still depends on the natural sample whose supply is very scarce. Therefore, the establishment of the method for a large scale production of Et 743 is desired and requires accomplishing an effective synthesizing process.

Since ET 743 is known as a medicine having high antineoplasticity, and phthalascidin induced from the intermediate product at the synthesis of Et 743 displays the same activity to ET 743, the establishment of an effective and mild method for synthesis of ET 743 and analogous compounds thereof is strongly desired.

Therefore, the subject of the present invention is to accomplish the effective method for total synthesis of Et 743, and further, to provide not only Et 743 but also analogous compounds.

To dissolve the subject, the present invention uses retrosynthetic analysis for easy synthesis. It will be possible to form a B ring by a ring forming reaction at the ortho position of phenol, which binds an A ring to inner molecular aldehyde in a compound generated by the 4-8 reaction. Further, the present invention contemplates that the generated compound by the 4-8 reaction can be synthesized based on the polycondensation reaction of general formula 4, and general formula 5 via a compound of general formula 3. Then the total synthesis of Et 743, which is the aimed compound, can be accomplished by way of the compounds represented by general formulae 5, 4, 3, 2 and 1 and the specific structure of general formulae 1 and 2. This synthetic route provides for the analogous compounds of Et 743.

Mechanism of action

The biological mechanism of action is believed to involve the production of superoxide near the DNA strand, resulting in DNA backbone cleavage and cell apoptosis. The actual mechanism is not yet known, but is believed to proceed from reduction of molecular oxygen into superoxide via an unusual auto-redox reaction on a hydroxyquinone moiety of the compound following. There is also some speculation the compound becomes ‘activated’ into its reactive oxazolidine form.

Schematic of the unique and complex mode of action of trabectedin. The antitumor effects of trabectedin are due to multiple mechanisms involving DNA binding in the minor groove, interactions with DNA repair mechanisms, modulation of transcription regulation, and induction of microenvironment changes.

References

- Lichter et al. Worthen LW, ed. “Food-drugs from the sea. Proc: Aug 20–23, 1972.” 173. Marine Tech Soc. pp. 117–127.

- Rinehart KL (January 2000). “Antitumor compounds from tunicates”. Med Res Rev 20(1): 1–27. doi:10.1002/(SICI)1098-1128(200001)20:1<1::AID-MED1>3.0.CO;2-A.PMID 10608919.

- “Potent cancer drugs made — Sea squirts provide recipe”.

- Rath CM et al (November 2011). “Meta-omic characterization of the marine invertebrate microbial consortium that produces the chemotherapeutic natural product ET-743″. ACS Chemical Biology 6 (11): 1244–56. doi:10.1021/cb200244t.PMC 3220770. PMID 21875091.

- “New Scientist”.

- E. J. Corey, David Y. Gin, and Robert S. Kania (1996). “Enantioselective Total Synthesis of Ecteinascidin 743″. J. Am. Chem. Soc. 118 (38): 9202–9203.doi:10.1021/ja962480t.

- C. Cuevas et al. (2000). “Synthesis of ecteinascidin ET-743 and phthalascidin PT-650 from cyanosafracin”. B. Org. Lett. 2: 2545–2548.

- “CHMP evaluation”.

- “PharmaMar website”.

- S.Korea approves Zeltia cancer drug Yondelis, Reuters.com, May 8, 2008

- Grogan, Kevin (3 May 2011). “J&J pulls submission for Zeltia’s Yondelis”.PharmaTimes Magazine (London, England). Online PharmaTimes. Archived from the original on 7 May 2011. Retrieved 7 May 2011.

- “PharmaMar website”.

| |

| SYSTEMATIC (IUPAC) NAME | |

|---|---|

| (1′R,6R,6aR,7R,13S,14S,16R)-6′,8,14-trihydroxy-7′,9-dimethoxy-4,10,23-trimethyl-19-oxo-3′,4′,6,7,12,13,14,16-octahydrospiro[6,16-(epithiopropano-oxymethano)-7,13-imino-6aH-1,3-dioxolo[7,8]isoquino[3,2-b][3]benzazocine-20,1′(2′H)-isoquinolin]-5-yl acetate | |

| CLINICAL DATA | |

| AHFS/DRUGS.COM | International Drug Names |

| LICENCE DATA | EMA:Link |

| LEGAL STATUS | |

| ROUTES | Intravenous |

| PHARMACOKINETIC DATA | |

| BIOAVAILABILITY | Not applicable (IV only) |

| PROTEIN BINDING | 94 to 98% |

| METABOLISM | Hepatic (mostly CYP3A4-mediated) |

| HALF-LIFE | 180 hours (mean) |

| EXCRETION | Mostly fecal |

| IDENTIFIERS | |

| CAS NUMBER | 114899-77-3 |

| ATC CODE | L01CX01 |

| PUBCHEM | CID 108150 |

| IUPHAR LIGAND | 2774 |

| DRUGBANK | DB05109 |

| CHEMSPIDER | 16736970  |

| UNII | ID0YZQ2TCP  |

| CHEMICAL DATA | |

| FORMULA | C39H43N3O11S |

| MOL. MASS | 761.84 g/mol |

……..

1 Corey, “Enantioselective Total Synthesis of Ecteinascidin 743“, J. Am. Chem. Soc. 1996, vol. 118, 9202-9203.

| 2 | * | Endo, “Synthetic Study on Ecteinascidin 743 Starting From D-Glucose“, Synlett 1999, No. 7, 1103-1105. |

| 3 | * | Endo, “Total Synthesis of Ecteinascidin 743“, J. Am. Chem. Soc. 2002, vol. 124, 6552-6554. |

| 4 | * | Hinterding, “Synthesis and In Vitro Evaluation of the Ras Farnesyltransferase Inhibitor Pepticinnamin E“, Angew. Chem. Int. Ed. 1998, 37, No. 9 1236-1239. |

| 5 | * | Tohma, “Synthesis of Optically Active alpha-Arylglycines: Stereoselective Mannich-Type Reaction with a New Chiral Template“, Synlett 2001, No. 7, 1179-1181.Hamprecht, D.W.; Berge, J.M.; Copley, R.C.B.; Eggleston, D.S.; Houge-Frydrych, C.S.V.; Jarvest, R.L.; Mensah, L.M.; O’Hanlon, P.J.; Pope, A.J.; Rittenhouse, S. Derivatives of the natural product SB-219383 and synthetic analogues: Potent inhibitors of bacterial tyrosyl tRNA synthetase 16th Int Symp Med Chem (September 18-22, Bologna) 2000, Abst PA-155Cuevas, C.; Perez, M.; Martin, M.J.; et al. Synthesis of ecteinascidin ET-743 and phathalascidin Pt-650 from cyanosafracin B Org Lett 2000, 2(16): 2545 |

| PATENT | SUBMITTED | GRANTED |

|---|---|---|

| Assay for identifying biological targets of polynucleotide-binding compounds [US2008096201] | 2008-04-24 | |

| Compounds of the saframycin-ecteinascidin series, uses, and synthesis thereof [US6936714] | 2004-07-01 | 2005-08-30 |

| Method For Total Synthesis Of Ecteinascidins And Intermediate Compounds Thereof [US7807833] | 2009-08-06 | 2010-10-05 |

| Method For Total Synthesis Of Ecteinascidins And Intermediate Compounds Thereof [US7820838] | 2009-02-05 | 2010-10-26 |

| Assay for identifying biological targets of polynucleotide-binding compounds [US7183054] | 2004-12-09 | 2007-02-27 |

↧

↧

KEBUZONE…….An antirheumatic agent.

KEBUZONE…….An antirheumatic agent.

Kebuzone (or ketophenylbutazone) is a non-steroidal anti-inflammatory drug.

Structural formula

4-(3-oxobutyl)-1,2-diphenylpyrazolidine-3,5-dione

4-(3-Oxobutyl)-1,2-diphenyl-3,5-pyrazolidinedione

Additional Names: 1,2-diphenyl-4-(g-ketobutyl)-3,5-pyrazolidinedione; 1,2-diphenyl-4-(3¢-oxobutyl)-3,5-dioxopyrazolidine; ketophenylbutazone; KPB

Trademarks: Chebutan; Chepirol; Chetazolidin (Zeria); Chetil; Copirene; Ketason; Ketazone (Beytout); Pecnon (Sanken); Phloguron (Steiner); Recheton

MF: C19H18N2O3

MW: 322.36

Percent Comp: C 70.79%, H 5.63%, N 8.69%, O 14.89%

Properties: Crystals, mp 115.5-116.5° or 127.5-128.5° depending on cryst form.

Melting point: mp 115.5-116.5° or 127.5-128.5° depending on cryst form

Therap-Cat: Antirheumatic.

- BRN 0308507

- Chebutan

- Chepirol

- Chetazolidin

- Chetil

- Copirene

- EINECS 212-715-7

- Hichillos

- Kebuzone

- Kebuzonum

- Kebuzonum [INN-Latin]

- Keobutane-jade

- Ketason

- Ketazone

- Ketophenylbutazone

- Ketophenylbutazonum

- KPB

- Pecnon

- Quebuzona

- Quebuzona [INN-Spanish]

- Recheton

- UNII-4VD83UL6Y6

Anti-inflammatory agents that are non-steroidal in nature. In addition to anti-inflammatory actions, they have analgesic, antipyretic, and platelet-inhibitory actions.They act by blocking the synthesis of prostaglandins by inhibiting cyclooxygenase, which converts arachidonic acid to cyclic endoperoxides, precursors of prostaglandins. Inhibition of prostaglandin synthesis accounts for their analgesic, antipyretic, and platelet-inhibitory actions; other mechanisms may contribute to their anti-inflammatory effects.

UV – range

IR – spectrum

Reference

- UV and IR Spectra. H.-W. Dibbern, R.M. Muller, E. Wirbitzki, 2002 ECV

- NIST/EPA/NIH Mass Spectral Library 2008

- Handbook of Organic Compounds. NIR, IR, Raman, and UV-Vis Spectra Featuring Polymers and Surfactants, Jr., Jerry Workman. Academic Press, 2000.

- Handbook of ultraviolet and visible absorption spectra of organic compounds, K. Hirayama. Plenum Press Data Division, 1967.

Brief background information

| SALT | ATC | FORMULA | MM | CAS |

|---|---|---|---|---|

| - | M01AA06 | C 19 H 18 N 2 O 3 | 322.36 g / mol | 853-34-9 |

| 4-(3-oxobutyl)-1,2-di(phenyl)pyrazolidine-3,5-dione | |

| CLINICAL DATA | |

|---|---|

| LEGAL STATUS | ? |

| IDENTIFIERS | |

| CAS NUMBER | 853-34-9  |

| ATC CODE | M01AA06 |

| PUBCHEM | CID 3824 |

| CHEMSPIDER | 3692  |

| UNII | 4VD83UL6Y6  |

| KEGG | D01567  |

| CHEBI | CHEBI:31749  |

| CHEMICAL DATA | |

| FORMULA | C19H18N2O3 |

| MOL. MASS | 322.35782 g/mol |

Application

- anti-inflammatory

- antirheumatic

- Synthesis pathway

Trade names

| COUNTRY | TRADE NAME | MANUFACTURER |

|---|---|---|

| Germany | Kebuzon | Steiner |

| France | Ketazon | Beytout |

| Italy | Chetopir | Sarm |

| Ukraine | no | no |

Formulations

- ampoules of 1 g / 5 ml;

- 250 mg capsule

Reference

- Synthesis of a)

- Denss, R. et al .: Helv. Chim. Acta (HCACAV) 40, 402 (1957).

- material:

- Kühn, M .: J. Prakt. Chem. (JPCEAO) 156 (II), 103 (1940).

- Synthesis b)

- AT 198 263 (Synfarma; appl. 1955).

References: Prepn: Deuss et al., US 2910481 (1959 to Geigy).

Review of pharmacology: Horakova et al.,Pharmacotherapeutica 1950-1959, 335-350 (1963), C.A. 60, 6072g (1964).

Metabolism: Nemecek et al., Arzneim.-Forsch. 16,1339 (1966); Queisnerova, Nemecek,Cesk. Farm. 20, 55 (1971), C.A. 75, 47077u (1971).

Herrenknecht, Christine; Guernet-Nivaud, Elisabeth; Lafont, Olivier; Guernet, Michel; Gueutin, Claire

Canadian Journal of Chemistry, 1988 , v. 66, pg. 1199 – 1202

Canadian Journal of Chemistry, 1988 , v. 66, pg. 1199 – 1202

Cizmarik; Lycka

Pharmazie, 1988 , v. 43, 11 pg. 794 – 795

Pharmazie, 1988 , v. 43, 11 pg. 794 – 795

Gueutin-Pelinard, Claire; Nivaud, Elisabeth; Boucly, Patrick; Guernet, Michel

Canadian Journal of Chemistry, 1981 , v. 59, pg. 759 – 762

Canadian Journal of Chemistry, 1981 , v. 59, pg. 759 – 762

Denss et al.

Helvetica Chimica Acta, 1957 , v. 40, pg. 402,406

Helvetica Chimica Acta, 1957 , v. 40, pg. 402,406

Patent: CS124279 , 1965 ;Chem.Abstr., 1968 , v. 69, 52134r

SPOFA; United Pharmaceutical Work Patent: FR1500627 , 1965 ;Chem.Abstr., 1968 , v. 69, 96715k

Nippon Shinyaju Co., Ltd. Patent: US5811547 A1, 1998 ;

Fisnerova,L. et al. Collection of Czechoslovak Chemical Communications, 1974 , v. 39, pg. 624 – 633

↧

EU approves Lilly diabetes drug Trulicity, dulaglutide

EU approves Lilly diabetes drug Trulicity, dulaglutide

Regulators in Europe have given the green light to Eli Lilly’s Trulicity, its once-weekly glucagon-like peptide-1 receptor agonist for type 2 diabetes.

Read more at: http://www.pharmatimes.com/Article/14-11-25/EU_approves_Lilly_diabetes_drug_Trulicity.aspx

Dulaglutide is a glucagon-like peptide 1 receptor agonist (GLP-1 agonist) for the treatment of type 2 diabetes that can be used once weekly.[1][2]GLP-1 is a hormone that is involved in the normalization of level of glucose in blood (glycemia). The FDA approved dulaglutide for use in the United States in September 2014.[3] The drug is manufactured by Eli Lilly under the brand name Trulicity.[3]

Mechanism of action

Dulaglutide binding to glucagon-like peptide 1 receptor, slows gastric emptying and increases insulin secretion by beta cells in the pancreas. Simultaneously the compound reduces the elevated glucagon secretion by alpha cells of the pancreas, which is known to be inappropriate in the diabetic patient. GLP-1 is normally secreted by L cells of the gastrointestinal mucosa in response to a meal.[4]

Medical uses[

The compound is indicated for adults with type 2 diabetes mellitus as an adjunct to diet and exercise to improve glycemic control. Dulaglutide is not indicated in the treatment of subjects with type 1 diabetes mellitus or patients with diabetic ketoacidosis. Dulaglutide can be used either stand-alone or in combination with other medicines for type 2 diabetes, in particularmetformin, sulfonylureas, thiazolidinediones, and insulin taken concomitantly with meals.[5]

Side effects

The most common side effects include gastrointestinal disorders, such as dyspepsia,decreased appetite, nausea, vomiting, abdominal pain, diarrhea.[6] Some patients may experience serious adverse reactions: acute pancreatitis (symptoms include persistent severe abdominal pain, sometimes radiating to the back and accompanied by vomiting),hypoglycemia, renal impairment (which may sometimes require hemodialysis). The risk of hypoglycemia is increased if the drug is used in combination with sulfonylureasorinsulin.[7][8]

Contraindications

The compound is contraindicated in subjects with hypersensitivity to active principle or any of the product’s components. As a precautionary measure patients with a personal or family history of medullary thyroid carcinoma or affected by multiple endocrine neoplasia syndrometype 2 should not take dulaglutide, because for now it is unclear whether the compound can increase the risk of these cancers.[9]

References

- JCourtney Aavang Tibble, Tricia Santos Cavaiola, Robert R Henry (2013). “Longer Acting GLP-1 Receptor Agonists and the Potential for Improved Cardiovascular Outcomes: A Review of Current Literature”. Expert Rev Endocrinol Metab 8 (3): 247–259.doi:10.1586/eem.13.20.

- “Lilly’s Once-Weekly Dulaglutide Shows Non-Inferiority to Liraglutide in Head-to-Head Phase III Trial for Type 2 Diabetes”. Eli Lilly. Feb 25, 2014.

- “FDA approves Trulicity to treat type 2 diabetes” (Press release). FDA. Sep 18, 2014.

- Nadkarni P, Chepurny OG, Holz GG (2014). “Regulation of glucose homeostasis by GLP-1″. Prog Mol Biol Transl Sci 121: 23–65. doi:10.1016/B978-0-12-800101-1.00002-8.PMC 4159612. PMID 24373234. Retrieved 2014-09-29.

- Terauchi Y, Satoi Y, Takeuchi M, Imaoka T (July 2014). “Monotherapy with the once weekly GLP-1 receptor agonist dulaglutide for 12 weeks in Japanese patients with type 2 diabetes: dose-dependent effects on glycaemic control in a randomised, double-blind, placebo-controlled study”. Endocr. J. PMID 25029955. Retrieved 2014-09-29.

- Nauck M, Weinstock RS, Umpierrez GE, Guerci B, Skrivanek Z, Milicevic Z (August 2014). “Efficacy and safety of dulaglutide versus sitagliptin after 52 weeks in type 2 diabetes in a randomized controlled trial (AWARD-5)”. Diabetes Care 37 (8): 2149–58.doi:10.2337/dc13-2761. PMID 24742660.

- Amblee A (April 2014). “Dulaglutide for the treatment of type 2 diabetes”. Drugs Today50 (4): 277–89. doi:10.1358/dot.2014.50.4.2132740. PMID 24918645.

- Monami M, Dicembrini I, Nardini C, Fiordelli I, Mannucci E (February 2014). “Glucagon-like peptide-1 receptor agonists and pancreatitis: a meta-analysis of randomized clinical trials”. Diabetes Res. Clin. Pract. 103 (2): 269–75.doi:10.1016/j.diabres.2014.01.010.PMID 24485345.

- Samson SL, Garber A (April 2013). “GLP-1R agonist therapy for diabetes: benefits and potential risks”. Curr Opin Endocrinol Diabetes Obes 20 (2): 87–97.doi:10.1097/MED.0b013e32835edb32. PMID 23403741. Retrieved 2014-09-30.

| IDENTIFIERS | |

|---|---|

| CAS NUMBER | 923950-08-7 |

| ATC CODE | None |

| CHEMICAL DATA | |

| FORMULA | C2646H4044N704O836S18 |

| MOL. MASS | 59669.81 g/mol |

↧

Antibacterial activities and antioxidant capacity of Aloe vera

Antibacterial activities and antioxidant capacity of Aloe vera

Organic and Medicinal Chemistry Letters 2013, 3:5 doi:10.1186/2191-2858-3-5

The electronic version of this article is the complete one and can be found online at:http://www.orgmedchemlett.com/content/3/1/5

Background

The aim of this study was to identify, quantify, and compare the phytochemical contents, antioxidant capacities, and antibacterial activities of Aloe vera lyophilized leaf gel (LGE) and 95% ethanol leaf gel extracts (ELGE) using GC-MS and spectrophotometric methods.

↧

↧

Peptide Has Promise for Treating Spinal Cord Injury

FEATURED STORY Peptide Has Promise for Treating Spinal Cord Injuryread athttp://www.dddmag.com/news/2014/12/peptide-has-promise-treating-spinal-cord-injury?et_cid=4300209&et_rid=523035093&type=cta | |||||||||

Case Western Reserve scientists have developed a new chemical compound that shows extraordinary promise in restoring function lost to spinal cord injury. The compound, which the researchers dubbed intracellular sigma peptide (ISP), allowed paralyzed muscles to activate in more than 80 percent of the animals tested. Read more...

|

↧

LEXIPAFANT

Lexipafant

CAS : 139133-26-9

N-Methyl-N-[[4-[(2-methyl-1H-imidazo[4,5-c]pyridin-1-yl)methyl]phenyl]sulfonyl]-L-leucine ethyl ester

N-methyl-N-[[a-(2-methyl-1H-imidazo[4,5-c]pyridin-1-yl)-p-tolyl]sulfonyl]-L-leucine ethyl ester

N-Methyl-N-[4-(2-methyl-1H-imidazo[4,5-c]pyridin-1-ylmethyl)phenylsulfonyl]-L-leucine ethyl ester

Manufacturers’ Codes: BB-882

DO6

GR-167089

ISV-611

GR-167089

ISV-611

UNII-H14917M9YW

Trademarks: Zacutex (Brit. Biotech)

MF: C23H30N4O4S

M Wt: 458.57

Percent Composition: C 60.24%, H 6.59%, N 12.22%, O 13.96%, S 6.99%

Properties: White crystalline solid from ethyl acetate, mp 105°. [a]D20 -6.7° (c = 2.0 in CDCl3).

Melting point: mp 105°

Optical Rotation: [a]D20 -6.7° (c = 2.0 in CDCl3)

Therap-Cat: Anti-inflammatory. (Nonsteroidal); Platelet Activating Factor Antagonist.

Lexipafant is a platelet-activating factor (PAF) antagonist that was in early clinical development at DevCo for the oral treatment of dementia and motor function disorders in HIV patients, intravenous treatment of acute pancreatitis, as well as for the prevention of certain serious renal and neurological complications experienced by patients undergoing cardiac surgery, including stroke. However, no recent developments of the drug candidate have been reported by the company.

Lexipafant was also being studied at British Biotech (now Vernalis) for the intravenous treatment of pancreatitis, but development for this indication was discontinued. In 2002, DevCo obtained from British Biotech exclusive rights to develop, manufacture and sell lexipafant for the treatment of human disease, excluding the fields of oncology and ophthalmology.

……………………………

……………………………………………

WO 1993016075

………………………………

WO 1995013064

Literature References:

Platelet activating factor (PAF) antagonist. Prepn: M. Whittaker, A. Miller, WO 9203422; eidem, US5200412 (1992, 1993 both to British Bio-Technology).

Structure-activity report: M. Whittaker et al., J. Lipid Mediators Cell Signalling 10, 151 (1994).

Pharmacology: F. M. Abu-Zidan et al., Pharmacol. Toxicol. 78, 23 (1996).

Clinical evaluation in acute pancreatitis: A. N. Kingsnorth et al., Br. J. Surg. 82, 1414 (1995).

↧

20 Superb Herbal Remedies for Abdominal Fat

read all

http://www.rapidhomeremedies.com/remedies-for-abdominal-fat.html

boost your metabolism excellently for the whole day.

Read all about Organic Spectroscopy on ORGANIC SPECTROSCOPY INTERNATIONAL ![]()

![]() amcrasto@gmail.com

amcrasto@gmail.com

↧

KAE 609, NITD 609, Cipargamin

Cipargamin, NITD 609

Cipargamin, NITD 609IUPAC Name: (3R,3'S)-5,7'-dichloro-6'-fluoro-3'-methylspiro[1H-indole-3,1'-2,3,4,9-tetrahydropyrido[3,4-b]indole]-2-one |

CAS Registry Number: 1193314-23-6

Synonyms: NITD609, NITD 609, NITD-609, GNF-609

KAE-609

NITD-609

Synonyms: NITD609, NITD 609, NITD-609, GNF-609

KAE-609

NITD-609

390.238, C19 H14 Cl2 F N3 O

(1'R,3'S)-5,7'-Dichloro-6'-fluoro-3'-methyl-1,2,2',3',4',9'-hexahydrospiro[indole-3,1'-pyrido[3,4-b]indole]-2-one

(1R,3S)-5′,7-Dichloro-6-fluoro-3-methyl-2,3,4,9-tetrahydrospiro[β-carboline-1,3′-indol]-2′(1′H)-one

NITD609 is an experimental synthetic antimalarial molecule belonging to the spiroindolone class.[1][2] The compound was developed at the Novartis Institute for Tropical Diseases in Singapore, through a collaboration with the Genomics Institute of the Novartis Research Foundation (GNF), the Biomedical Primate Research Centre and the Swiss Tropical Institute. NITD609 is a novel, synthetic antimalarial molecule belonging to the spiroindolone class, awarded MMV Project of the Year 2009.

It is structurally related to GNF 493, a compound first identified as a potent inhibitor of Plasmodium falciparum growth in a high throughput phenotypic screen of natural products conducted at the Genomics Institute of the Novartis Research Foundation in San Diego, California in 2006. NITD609 was discovered by screening the Novartis library of 12,000 natural products and synthetic compounds to find compounds active against Plasmodium falciparum. The first screen turned up 275 compounds and the list was narrowed to 17 potential candidates.

KAE609 (cipargamin; formerly NITD609, Novartis Institute for Tropical Diseases) is a new synthetic antimalarial spiroindolone analogue with potent, dose-dependent antimalarial activity against asexual and sexual stages of Plasmodium falciparum.http://www.nejm.org/doi/full/10.1056/NEJMoa1315860

KAE609 shows promise as next generation treatment for malaria

http://www.novartis.com/newsroom/media-releases/en/2014/1843976.shtml- KAE609 is the first antimalarial drug candidate with a novel mechanism of action to achieve positive clinical proof-of-concept in over 20 years

- KAE609 was tested in adult patients with uncomplicated malaria and showed a median parasite clearance time of 12 hours, including in patients with resistant infections[1]

- For more than a decade, Novartis has been a leader in the fight against malaria, setting the current gold standard for treatment and building one of the strongest malaria pipelines in the industry

KAE609 shows promise as next generation treatment for malaria

- KAE609 is the first antimalarial drug candidate with a novel mechanism of action to achieve positive clinical proof-of-concept in over 20 years

- KAE609 was tested in adult patients with uncomplicated malaria and showed a median parasite clearance time of 12 hours, including in patients with resistant infections[1]

- For more than a decade, Novartis has been a leader in the fight against malaria, setting the current gold standard for treatment and building one of the strongest malaria pipelines in the industry

Basel, Switzerland, July 30, 2014- Today, Novartis published clinical trial results in the New England Journal of Medicine showing that KAE609 (cipargamin), a novel and potent antimalarial drug candidate, cleared the parasite rapidly in Plasmodium falciparum (P. falciparum) and Plasmodium vivax (P. vivax) uncomplicated malaria patients[1]. Novartis currently has two drug candidates in development. Both KAE609 and KAF156 are new classes of anti-malarial compounds that treat malaria in different ways from current therapies, important to combat emerging drug resistance. Novartis has also identified PI4K as a new drug target with potential to prevent, block and treat malaria.

"Novartis is in the fight against malaria for the long term and we are committed to the continued research and development of new therapies to eventually eliminate the disease," said Joseph Jimenez, CEO of Novartis. "With two compounds and a new drug target currently under investigation, Novartis has one of the strongest malaria pipelines in the industry."

Malaria is a life-threatening disease primarily caused by parasites (P. falciparum and P. vivax) transmitted to people through the bites of infected Anopheles mosquitoes. Each year it kills more than 600,000 people, most of them African children[2].

"KAE609 is a potential game-changing therapy in the fight against malaria," said Thierry Diagana, Head of the Novartis Institute for Tropical Diseases (NITD), which aims to discover novel treatments and prevention methods for major tropical diseases. "Novartis has given KAE609 priority project status because of its unique potential of administering it as a single-dose combination therapy."

In June 2012, 21 patients infected by one of the two main malaria-causing parasite types took part in a proof-of-concept clinical study conducted in Bangkok and Mae Sot near the Thailand/Burma border where resistance to current therapies had been reported. Researchers saw rapid parasite clearance in adult patients (median of 12 hours)[2] with uncomplicated P. vivax or P. falciparum malaria infection including those with resistant parasites. No safety concerns were identified, however the study was too small for any safety conclusions.

"The growing menace of artemisinin resistance threatens our current antimalarial treatments, and therefore our attempts to control and eliminate falciparum malaria," said Nick White, Professor of Tropical Medicine at Mahidol University in Thailand and lead author of the NEJM article. "This is why we are so enthusiastic about KAE609; it is the first new antimalarial drug candidate with a completely novel mechanism of action to reach Phase 2 clinical development in over 20 years."

KAE609, the first compound in the spiroindolone class of treatment, works through a novel mechanism of action that involves inhibition of a P-type cation-transporter ATPase4 (PfATP4), which regulates sodium concentration in the parasite. Because KAE609 also appears to be effective against the sexual forms of the parasite, it could potentially help prevent disease transmission. The clinical trial was done in collaboration with the Wellcome Trust-Mahidol University - Oxford Tropical Medicine Research Programme. Research was supported by the Wellcome Trust, Singapore Economic Development Board, and Medicines for Malaria Venture.

KAE609 represents one of two new classes of antimalarial compounds that Novartis has discovered and published in the last four years.[3],[4] This drug candidate has shown potent in vitro activity against a broad range of parasites that have developed drug resistance against current therapies. KAE609 is currently being planned for Phase 2b trials.

References

[1] http://www.nejm.org/doi/full/10.1056/NEJMoa1315860

[2] World Health Organization, http://www.who.int/mediacentre/factsheets/fs094/en/

[3] Spiroindolones, a Potent Compound Class for the Treatment of Malaria, KAE609, Science, Sept. 2010

[4] Imaging of Plasmodium liver stages to drive next generation antimalarial drug discovery. Science Express, Nov. 17, 2011

[1] http://www.nejm.org/doi/full/10.1056/NEJMoa1315860

[2] World Health Organization, http://www.who.int/mediacentre/factsheets/fs094/en/

[3] Spiroindolones, a Potent Compound Class for the Treatment of Malaria, KAE609, Science, Sept. 2010

[4] Imaging of Plasmodium liver stages to drive next generation antimalarial drug discovery. Science Express, Nov. 17, 2011

The current spiroindolone was optimized to address its metabolic liabilities leading to improved stability and exposure levels in animals. As a result, NITD609 is one of only a handful of molecules capable of completely curing mice infected withPlasmodium berghei (a model of blood-stage malaria).

Given its good physicochemical properties, promising pharmacokinetic and efficacy profile, the molecule was recently approved as a preclinical candidate and is now entering GLP toxicology studies with the aim of entering Phase I studies in humans in late 2010. If its safety and tolerability are acceptable, NITD609 would be the first antimalarial not belonging to either the artemisinin or peroxide class to go into a proof-of-concept study in malaria.

If NITD609 behaves similarly in people to the way it works in mice, it may be possible to develop it into a drug that could be taken just once - far easier than current standard treatments in which malaria drugs are taken between one and four times a day for up to seven days. NITD609 also has properties which could enable it to be manufactured in pill form and in large quantities. Further animal studies have been performed and researchers have begun human-stage trials.

| |

| Identifiers | |

| ChemSpider | 24662493 |

| Jmol-3D images | Image 1 |

| Properties | |

| Molecular formula | C19H14Cl2FN3O |

| Molar mass | 390.24 g mol−1 |

Leishmaniasis is caused by one of more than twenty (20) varieties of parasitic protozoa that belong to the genus Leishmania, and is transmitted by the bite of female sandflies. Leishmaniasis is endemic in some 90 countries, including many tropical and sub-tropical areas.

There are four main forms of leishmaniasis. Visceral leishmaniasis, also called kala-azar, is the most serious form and is caused by the parasite Leishmania donovani. Patients who develop visceral leishmaniasis can die within months unless they receive treatment. The two main therapies for visceral leishmaniasis are the antimony derivatives sodium stibogluconate (Pentostam®) and meglumine antimoniate (Glucantim®). Sodium stibogluconate has been used for about 70 years and resistance to this drug is a growing problem. In addition, the treatment is relatively long and painful, and can cause undesirable side effects. Human African Trypanosomiasis, also known as sleeping sickness, is a vector-bome parasitic disease. The parasites concerned are protozoa belonging to the Trypanosoma Genus. They are transmitted to humans by tsetse fly {Glossina Genus) bites which have acquired their infection from human beings or from animals harbouring the human pathogenic parasites.

Chagas disease (also called American trypanosomiasis) is another human parasitic disease that is endemic amongst poor populations on the American continent. The disease is caused by the protozoan parasite Trypanosoma cruzi, which is transmitted to humans by blood-sucking insects. The human disease occurs in two stages: the acute stage, which occurs shortly after the infection, and the chronic stage, which can develop over many years. Chronic infections result in various neurological disorders, including dementia, damage to the heart muscle and sometimes dilation of the digestive tract, as well as weight loss. Untreated, the chronic disease is often fatal.

The drugs currently available for treating Chagas disease are nifurtimox and benznidazole. However, problems with these current therapies include their adverse side effects, the length of treatment, and the requirement for medical supervision during treatment. Furthermore, treatment is really only effective when given during the acute stage of the disease. Resistance to the two frontline drugs has already arisen. The antifungal agent amphotericin b has been proposed as a second-line drug, but this drug is costly and relatively toxic.

SYNTHESIS..........WILL BE UPDATED

...........................................

SCHEME G: Preparation of (lR,3S)-5',7-dichloro-6-fluoro-3-methyl-2,3,4,9- tetrahydrospiro[β-carboline-l,3'-indol-2'(l'iϊ)-one (35) and (lR,3S)-5'-chloro-6-fluoro-3- methyl-2,3,4,9-tetrahydrospiro[β-carboline-l,3'-indoI-2'(l'H0-one (36)

Step 1 : POCl3 (2.43 mL, 26.53 mmol) was added dropwise to N, N-dimethylformamide (15.0 mL) at -20 °C and stirred below -5 0C for one hour. A solution of 6-chloro-5-fluoroindole (3.0 g, 17.69 mmol) in dimethylformamide (5.0 mL) was added dropwise to the above reaction mixture at -20 °C. The salt-ice bath was removed and the reaction mixture was warmed to 35 0C, After one hour, the reaction was poured onto ice and basified by solid sodium bicarbonate and extracted with ethyl acetate. The combined organic layer was washed with water and then concentrated to give 6-chloro-5-fluoro-1H-indole-3-carbaldehyde (3.4 g, 97 %) as a light brown solid. 1H ΝMR (500 MHz, CDCl3): δ 10.02 (s, 1 H), 8.10 (d, IH, J = 9.5 Hz), 7.87 (s, 1 H), 7.49 (d, IH, J= 5.5 Hz).

Step 2: The solution (0.2 M) of 6-chloro-5-fluoro-1H-indole-3-carbaldehyde (4.0 g, 20.24 mmol) in nitroethane (100 mL) was refluxed with ammonium acetate (1.32 g, 0.85 mmol) for 4 hours. The reaction mixture was concentrated under vacuum to remove nitroethane, diluted with ethylacetate and washed with brine. The organic layer was concentrated to give 6-chloro-5- fluoro-3-(2-nitro-propenyl)-1H-indole (5.0 g, 97 %) as a reddish orange solid. 1H ΝMR (500 MHz, CDCl3): δ 8.77 (s, IH), 8.32 (s, IH), 7.58 (d, IH, J= 2.5 Hz), 7.54 (d, IH, J = 9 Hz), 7.50 (d, IH, J= 5.9 Hz), 2.52 (s, 3H). Step 3: A solution of 6-chloro-5-fluoro-3-(2-nitro-propenyl)-1H-indole (5.0 g, 19.63 mmol) in tetrahydrofuran (10 mL) was added to the suspension of lithium aluminium hydride (2.92 g, 78.54 mmol) in tetrahydrofuran (20 mL) at 0 0C and then refluxed for 3 hours. The reaction mixture was cooled to 0 °C, and quenched according to the Fischer method. The reaction mixture was filtered through celite and the filtrate concentrated to give 2-(6-chloro-5-fluoro-1H-indol-3- yl-1-methyl-ethylamine (4.7 g crude) as a viscous brown liquid. The residue was used without further purification. 1H NMR (500 MHz, CDCl3): δ 8.13 (s, IH), 7.37 (d, IH, 6.Hz), 7.32 (d, IH, J = 10 Hz), 7.08 (s, IH), 3.23-3.26 (m, IH), 2.77-2.81 (m, IH), 2.58-2.63 (m, IH), 1.15 (d, 3H, J= 6.5 Hz).

Step 4: A mixture of 2-(6-chloro-5-fluoro-1H-indol-3-yl-l-methyl-ethylamine (4.7 g, 20.73 mmol), 5-chloroisatin (3.76 g, 20.73 mmol) and p-toluenesulphonic acid (394 mg, 2.07 mmol) in ethanol (75 mL) was refluxed overnight. The reaction mixture was concentrated to remove ethanol, diluted with ethyl acetate and washed with saturated aqueous NaHCO3. The organic layer was concentrated to give a brown residue, which was purified by silica gel chromatography (20 % ethyl acetate in hexane) to provide the corresponding racemate (4.5 g, 56 %) as a light yellow solid. The racemate was separated into its enantiomers by chiral chromatography to provide 35.

Compound 36 can be obtained in a similar fashion from 5-fluoroindole.

Alternatively 35 and 36 were be prepared in enantiomerically pure form by the following scheme.

SCHEME H: Alternative preparation of (lR,3S)-5',7-dichloro-6-fluoro-3-methyl-2,3,4,9- tetrahydrospiro[β-carboline-l,3'-indol-2'(1'H)-one (35)

Step 1 : To a solution of 6-chloro-5-fluoroindole (1.8 g, 10.8 mmol) and Ac2O (10 niL) in AcOH (3OmL) was added L-serine (2.2 g, 20.9 mmol), the mixture was heated to 80 °C. After TLC indicated the reaction was complete, the mixture was cooled to 0 °C, neutralized to pH 11 , and washed with MTBE. The aqueous phase was acidified to pH 2 and extracted with EtOAc. The combined organic layers were washed with water and bπne, dπed with Na2SO4, filtered, and concentrated. The residue was purified with chromatography (Petroleum ether /EtOAc 1:1) to give 2-acetylamino-3-(6-chloro-5-fluoro-1H-mdol-3-yl)-propπonic acid as a light yellow solid (1.2 g, 37% yield).

Step 2: 2-Acetylamino-3-(6-chloro-5-fluoro-1H-indol-3-yl)-proprionic acid (2.5g, 8.4mmol) was dissolved in aqueous NaOH (IN, 10 niL) and water added (70 mL). The mixture was heated to 37-380C and neutralized with HCl (IN) to pΗ 7.3-7.8. L-Aminoacylase (0.5 g) was added to the mixture and allowed to stir for 2 days, maintaining 37-380C and pΗ 7.3-7.8. The mixture was heated to 60 °C for another hour, concentrated to remove part of water, cooled and filtered. The filtrate was adjusted to pΗ 5.89 and filtered again. The filtrate was adjusted to pΗ 2.0 and extracted with EtOAc. The combined organic layer was dried over Na2SO4, filtered, concentrated and the residue was purified with chromatography (petroleum ether /EtOAc 1 : IEtOAc) to give R- 2-acetylamino-3-(6-chloro-5-fluoro-1H-mdol-3-yl)-propπonic acid as a light yellow solid (1.2 g, 48% yield). Step 3: R-2-acetylamino-3-(6-chloro-5-fluoro-1H-indol-3-yl)-proprionic acid (1.2 g, 4.0 mmol) was dissolved in HCl (6N, 10 mL) and the mixture heated to reflux for 4 hours, and then concentrated to dryness. Toluene (50 mL) was added to the residue and concentrated to dryness to remove water and HCl. The residue was dried under vacuum and then dissolved in MeOH (20 mL). To the solution was added dropwise SOCl2 (0.5 mL, 6.8 mmol) at 0 °C, and the mixture was stirred overnight. After removal of solvent, the residue was dissolved in THF/water (40/10 mL) and NaHCO3 (1.0 g, 11.9 mmol) was added portionwise. Upon basifϊcation, BoC2O (1.2 g, 5.5 mmol) added at 0 °C and allowed to stir at room temperature. After TLC indicated the reaction was finished, EtOAc was added and separated and the aqueous layer was extracted with EtOAc. The combined organic layers were washed with water and brine, dried with Na2SO4, filtered, concentrated and the residue was purified with chromatography (petroleum ether /EtOAc: 5/1) to give R-2-tert-butoxycarbonylamino-3-(6-chloro-5-fluoro-l/-/-indol-3-yl)-proprionic acid methyl ester 460 g, 31% yield for 3 steps).

Step 4: To a solution of R-2-tert-butoxycarbonylamino-3-(6-chloro-5-fluoro-l//-indol-3-yl)- proprionic acid methyl ester (460mg, 1.2mmol) in dry ether (20 mL) was added portionwise LiAlH4 (92 mg, 2.4 mmol) at 0 °C. The mixture was heated to reflux for 2 hours. After TLC indicated the reaction was finished, the mixture was cooled and carefully quenched with Na2SO4. The mixture was filtered and the filtrate was washed with saturated aqueous NH4Cl and water, dried with Na2SO4, filtered, concentrated to give a crude product (400 mg), which was used without further purification.

Step 5: To a solution of the crude product (400 mg, 1.2mmol) and Et3N (0.3 mL, 2.2 mmol) in CH2Cl2 (5 mL) was added MsCl (160 mg, 1.4 mmol) dropwise at 0 °C. The mixture was stirred for 2 hours at room temperature. After TLC indicated the reaction was completed, the mixture was washed with water and brine, dried with Na2SO4, filtered, concentrated and the residue was purified with chromatography (petroleum ether/EtOAc 5:1) to give methansulfonic acid (R)-2- ?ert-butoxycarbonylamino-3-(6-chloro-5-fluoro-1H-indol-3-yl)-propyl ester as a light yellow solid (300 mg, 57% yield, 2 steps)

Step 6: To a solution of mesylate (300 mg, 0.7mmol) in dry ether (20 mL) was added portionwise LiAlH4 (55 mg, 1.4 mmol) at 0 °C. The mixture was stirred at room temperature overnight. After TLC indicated the reaction was finished, the mixture was cooled and carefully quenched with Na2SO4. The mixture was filtered and the filtrate was washed with saturated aqueous NH4Cl and water, dried with Na2SO4, filtered, concentrated and the residue was purified with chromatography (petroleum ether/EtOAc 10: 1) to give [(5)-2-(6-chloro-5-fluoro-1H-indol-3-yl)- 1 -methyl-ethyl] -carbamic acid tert-butyl ester as a light yellow solid (200 mg, 87% yield).

Step 7: A solution of [(S)-2-(6-chloro-5-fluoro-1H-indol-3-yl)-l-methyl-ethyl]-carbamic acid tert-butyl ester (200 mg, 0.6 mmol) in HCl/MeOH (10 mL) was stirred at room temperature. After TLC indicated the reaction was finished, the mixture was concentrated to remove the solvent. To the residue was added EtOAc (5OmL), and the mixture was neutralized with saturated NaHCO3 to pH 8~9, and then extracted with EtOAc. The combined organic phases were dried with Na2SO4, filtered, concentrated to give a crude (S)-2-(6-chloro-5-fluoro-1H-indol-3-yl)-l- methyl-ethylamine which was used without further purification.

Step 8: To a solution of (5)-2-(6-chloro-5-fluoro-1H-indol-3-yl)-l-methyl-ethylamine (120 mg, 0.5 mmol) in EtOH (1OmL) was added 5-chloroisatin (90 mg, 0.5 mmol) and p-TsOΗ (8 mg, 0.04 mmol). The mixture was heated in a sealed tube at 1100C for 16 hours. After TLC indicated the reaction was finished, the mixture was cooled and concentrated. The residue was dissolved in EtOAc (2OmL) and washed with NaOH (IN) and brine, dried with Na2SO4, filtered, concentrated and the residue was purified with chromatography (petroleum ether/EtOAc 5:1) to give 36 (150mg, 64% yield over two steps).

Example 48 (15,3R)-5'-Chloro-3-methyl-2,3,4,9-tetrahydrospiro[β-carboline-l,3'-indol]-2'(l'JH)-one

(35)

35

Compound 35 may be prepared according to Scheme F using the same or analogous synthetic techniques and/or substituting with alternative reagents.

(lS^RVS'-Chloro-S-methyl-l^^^-tetrahydrospirotβ-carboline-l.S'-indoll-l^l'ZO-one: 1H NMR (300 MHz, DMSO-^6): δ 10.45 (s, IH), 10.42 (s, IH), 7.43 (d, J= 7.5 Hz, IH), 7.31 (dd, J = 2.1, 8.4 Hz, IH), 7.16 (d, J = 7.2 Hz, IH), 7.05-7.02 (m, 2H), 7.00-6.96 (m, IH), 6.92 (d, J = 8.1 Hz, IH), 3.98-3.86 (m, IH), 2.78 (dd, J= 3.6, 14.9 Hz, IH), 2.41 (dd, J= 4.5, 25.5 Hz, IH), 1.18 (d, J= 6.3 Hz, 3H); MS (ESI) m/z 338.0 (M+H)+.

Chiral compounds such as 36 and 37 can be prepared according to Scheme G or H using the same or analogous synthetic techniques and/or substituting with alternative reagents. Example 49

(IR^^-S'.T-Dichloro-ό-fluoro-S-methyl-l^^^-tetrahydrospiroIβ-carboline-l^'-indol]- 2\VH)-one (36)

36

35: 1H NMR (500 MHz, DMSO-Jd) δ 10.69 (s, IH), 10.51 (s, IH), 7.43 (d, J = 10.0 Hz, IH), 7.33 (dd, J= 8.4, 2.2 Hz, IH), 7.27 (d, J= 6.5 Hz, IH), 7.05 (d, J= 2.3, IH), 6.93 (d, J= 8.5 Hz, IH), 3.91 (m, IH), 3.13 (bd, J= 6.2 Hz, IH), 2.74 (dd, J= 15.0 , 3.0 Hz, IH), 2.35 (dd, J= 15.0, 10.3, IH), 1.15 (d, J= 6.0, 3H);

MS (ESI) m/z 392.0 (M+2H)+;

[α]25D = + 255.4°

Example 50

(lS,3R)-5',7-Dichloro-6-fluoro-3-methyI-2,3,4,9-tetrahydrospiro[β-carboline-l,3'-indol]- 2'(l'H)-one (37)

37

(lS^^-S'^-Dichloro-o-fluoro-S-methyl^jS^^-tetrahydrospirojP-carboline-l-S'-indol]- 2'(l'H)-one: 1H NMR (500 MHz, CDCl3) δ 8.49 (s, IH), 7.54 (s, IH), 7.24 (d, J= 9.7 Hz, IH), 7.21 (dd, J = 8.6, 2.0 Hz, IH), 7.14 (d, J= 6.0 Hz, IH), 7.11 (d, J= 1.8, IH), 6.77 (d, J= 8.3 Hz, IH), 4.14 (m, IH), 2.89 (dd, J = 15.4, 3.7 Hz, IH), 2.49 (dd, J = 15.3, 10.5, IH), 1.68 (bs, IH), 1.29 (d, J= 6.4 Hz, 3H); MS (ESI) m/z 392.0 (M+2H)+; [α]25D -223.3°

.............................................

US 2011275613

Prior art:

(1 'R, 3'S)-5, 7'-dichloro-6'-fIuoro-3'-methyl-2', 3',4', 9'-tetrahydrospiro[indoline-3, 1 - pyrido[3,4-b]indol]-2-one (eg. a compound of formula (IV), which comprises a spiroindolone moiety) and a 6-steps synthetic method for preparing, including known chiral amine intermediate compound (MA) are known (WO 2009/132921 ):

he present invention relates to processes for the preparation of spiroindolone compounds, such as (1'R,3'S)-5, 7'-dichloro-6'-fIuoro-3'-methyl-2',3',4',9'- tetrahydrospiro[indoline-3, 1 '-pyhdo[3.4-b]indol]-2-one.

(1 'R, 3'S)-5, 7'-dichloro-6'-fluoro-3'-methyl-2', 3',4 9'-tetrahydrospiro[indoline-3, 1 '- pyrido[3, 4-b]indol]-2-one is useful in the treatment and/or prevention of infections such as those caused by Plasmodium falciparum, Plasmodium vivax, Plasmodium malariae, Plasmodium ovale, Trypanosoma cruzi and parasites of the Leishmania genus such as, for example, Leishmania donovani., and it has the following structure:

(IVA)

(1 'R, 3'S)-5, 7'-dichloro-6'-fluoro-3'-methyl-2 3', 4', 9'-tetrahydrospiro[indoline-3, 1 - pyhdo[3, 4-b]indol]-2-one and a synthesis thereof are described in WO 2009/132921 Al in particular in Example 49 therein.

(1 'R, 3'S)-5, 7'-dichloro-6'-fluoro-3'-methyl-2', 3',4 9'-tetrahydrospiro[indoline-3, 1 '- pyrido[3, 4-b]indol]-2-one is useful in the treatment and/or prevention of infections such as those caused by Plasmodium falciparum, Plasmodium vivax, Plasmodium malariae, Plasmodium ovale, Trypanosoma cruzi and parasites of the Leishmania genus such as, for example, Leishmania donovani., and it has the following structure:

(IVA)

(1 'R, 3'S)-5, 7'-dichloro-6'-fluoro-3'-methyl-2 3', 4', 9'-tetrahydrospiro[indoline-3, 1 - pyhdo[3, 4-b]indol]-2-one and a synthesis thereof are described in WO 2009/132921 Al in particular in Example 49 therein.

Example 10: Process for Conversion of Compound (IA) to Compound (IIA) in 30g Scale

458.97

152.48g /so-propylamine hydrochloride and 0.204g pyridoxalphosphate monohydrate were dissolved in 495ml water while stirring. To this yellow clear solution a solution of 30. Og ketone in 85ml poly ethylene glycol (average mol weight 200) within 15 minutes. Upon addition the ketone precipitates as fine particles which are evenly distributed in the reaction media. To the suspension 180ml triethanolamine buffer (0.1 mol/l, pH 7) were added and the pH was adjusted to 7 by additon of aqueous sodium hydroxide solution (1 mol/l). The reaction mixture is heated to 50°C and a solution of 1.62g transaminase SEQ ID NO: 134 dissolved in 162ml triethanolamine buffer (0 1 mol/l, pH 7) is added. The reaction mixture is continiously kept at pH 7 by addition of 1 mol/l aqueous sodium hydroxide solution. The reaction mixture is stirred 24h at 50°C and a stream of Nitrogen is blown over the surface of the reaction mixture to strip off formed acetone. The reaction mixture is then cooled to 25°C and filtered over a bed of cellulose flock. The pH of the filtrate is adjusted to «1 by addition of concentrated sulfuric acid. The acidified filtrated is extracted with 250 ml /so-Propyl acetate. The layers are separated and the pH of the aqueous phase is adjusted to ¾10 by additon of concentrated aqueous sodium hydroxide solution. The basified aqueous phase is extracted with /'so-propyl acetate. The layers are seperated and the organic phase is washed with 100 ml water. The organic phase is concentrated by distillation to 2/3 of its origin volume. In a second reactor 33.98g (+)- camphor sulfonic acid is dissolved in 225 ml /'so-propyl acetate upon refluxing and the concentrated organic phase is added within 10 minutes. After complete addition the formed thin suspension is cooled to 0°C within 2 hours and kept at 0°C for 15 hours. The precipitated amine-(+)-camphor sulfonate salt is filtered, washed with 70 ml /so-propyl acetate and dried at 40°C in vaccuum yielding 51.57g of colourless crystals (84.5% yield t.q.)

Analytical Data

IR:

v (crn 1)=3296, 3061 , 2962, 2635, 2531 , 2078, 1741 , 1625, 1577, 1518, 1461 , 1415, 1392, 1375, 1324, 1302, 1280, 1256, 1226, 1 170, 1 126, 1096, 1041 , 988, 966, 937, 868, 834, 814, 790, 766, 746, 719, 669, 615.

LC-MS (ESI +):

Ammonium ion: m/z =227 ([M+H]), 268 ([M+H+CH3CN]), 453 ([2M+H]).

Camphorsulfonate ion: m/z =250 ([M+NH4]), 482 ([2M+NH4]).

LC-MS (ESI -):

Camphorsulfonate ion: m/z=231 ([M-H]), 463 ([2M-H]).

1H-NMR (DMSO-d6, 400 MHz):

1 1.22 (br. s., 1 H), 7.75 (br. s., 3H), 7.59 (d, J = 10.3 Hz, 1 H), 7.54 (d, J = 6.5 Hz, 1 H), 7.36 (d, J = 2.3 Hz, 1 H), 3.37 - 3.50 (m, 1 H), 2.98 (dd, J = 14.3, 5.8 Hz, 1 H), 2.91 (d, J = 14.8 Hz, 1 H), 2,81 (dd, J = 14.3, 8.0 Hz, 1 H), 2.63 - 2.74 (m, 1 H), 2.41 (d, J = 14.6 Hz, 1 H), 2.24 (dt, J = 18.3, 3.8 Hz, 1 H), 1 .94 (t, J = 4.4 Hz, 1 H), 1.86 (dt, J = 7.4, 3 6 Hz, 1 H), 1.80 (d, J = 18.1 Hz, H), 1.23 - 1 .35 (m, 2H), 1.15 (d, J = 6.3 Hz, 3H), 1.05 (s, 3H), 0.74 (s, 3H)

Free Amine (obtained by evaporatig the iso-Propylacetate layer after extraction of the basified aqueous layer):

1H NMR (400MHz, DMSO-d6): 11 .04 (br. s., 1 H), 7.50 (d, J = 10.5 Hz, 1 H), 7.48 (d, J = 6.5 Hz, 1 H), 7.25 (s, 1 H), 3.03 (sxt, J = 6.3 Hz, 1 H), 2.61 (dd, J - 14.3, 6.5 Hz, 1 H), 2.57 (dd, J = 14.1 , 6.5 Hz, 1 H), 1.36 (br. s., 2H), 0.96 (d, J = 6.3 Hz, 3H)

Example 11: Process for Conversion of Compound (HA) to Compound (IVB)

3. solvent exchange to TP

13.62 g 5-chloroisatin is suspended in 35 ml /so-propanol and 2.3 g triethyl amine is added. The suspension is heated to reflux and a solution of 34.42g amine-(+)-camphor sulfonate salt dissolved in 300 ml /'so-propanol is added within 50 minutes. The reaction mixture is stirred at reflux for 17 hours. The reaction mixture is cooled to 75°C and 17.4g (+)-camphorsulfonic acid are added to the reaction mixture. Approximately 300 ml /so- propanol are removed by vacuum distillation. Distilled off /so-propanol is replaced by iso- propyl acetate and vacuum distillation is continued. This is distillation is repeated a second time. To the distillation residue 19 ml ethanol and 265 ml ethyl acetate is added and the mixture is heated to reflux. The mixture is cooled in ramps to 0°C and kept at 0°C for 24 hours. The beige to off white crystals are filtered off, washed with 3 portions (each 25 ml) precooled (0°C) ethylacetate and dried in vacuum yielding 40.3 g beige to off white crystals. (86.3% yield t.q.)

IR:

v (crrr)= 3229, 3115, 3078, 3052, 2971 , 2890, 2841. 2772. 2722, 2675, 2605, 2434. 1741 , 1718, 1621 , 1606, 1483, 1460, 1408, 1391 , 1372, 1336, 1307, 1277, 1267, 1238, 1202, 1 184, 1 162, 1 149, 1 128, 1067, 1036, 987, 973, 939, 919, 896, 871 , 857, 843, 785, 771 , 756, 717, 690, 678, 613.

LC-MS (ESI +):

Ammonium ion: m/z =390 ([M+H]), 431 ([M+H+CH3CN]) Camphorsulfonate ion: m/z =250 ([M+NH4]), 482 ([2M+NH4])

LC-MS (ESI -):

Camphorsulfonate ion: m/z=231 ([M-H]), 463 ([2M-H])

1H NMR (DMSO-d6, 600 MHz):

11.49 (s, 1 H), 1 1.23 (s, 1 H), 10.29 - 10.83 (m, 1 H), 9.78 - 10.31 (m, 1 H), 7.55 - 7.60 (m, 2H), 7.52 (s, 1 H), 7.40 (d, J = 6.2 Hz, H), 7.16 (d, J = 8.8 Hz, 1 H), 4.52 - 4.63 (m, 1 H). 3.20 (dd, J = 16.3, 4.2 Hz, 1 H), 2.96 (dd, J = 16.1 , 11.3 Hz, 1 H), 2.90 (d, J = 15.0 Hz, 1 H), 2.56 - 2.63 (m, 1 H), 2.39 (d, J = 14.6 Hz, 1 H), 2.21 (dt, J = 18.0, 3.8 Hz, 1 H), 1.89 - 1.93 (m, 1 H), 1.81 (ddd, J = 15.3, 7.8, 3.7 Hz, 1 H), 1.76 (d, J = 18.3 Hz, 1 H), 1 .53 (d, J = 6.6 Hz, 3H), 1.20 - 1.33 (m, 2H), 0.98 (s, 3H), 0.70 (s, 3H)

Example 12: Process for Preparing a Compound of formula (IVA) 1/z Hydrate

mw622.54 .............................................................................mw399.25

In a 750ml reactor with impeller stirrer 50g of compound (IVB) salt were dissolved in 300ml Ethanol (ALABD) and 100 ml deionised Water (WEM). The clear, yellowish sollution was heated to 58°C internal temperature. To the solution 85 g of a 10% aqueous sodium carbonate solution was added within 10 minutes. The clear solution was particle filtered into a second reaction vessel. Vessel and particle filter were each rinsed with 25 ml of a mixture of ethanohwater (3:1 v/v) in the second reaction vessel. The combined particle filtered solution is heated to 58°C internal temperature and 200ml water (WEM) were added dropwise within 15 minutes. Towards the end of the addition the solution gets turbid.

The mixture is stirred for 10 minutes at 58°C internal temperature and is then cooled slowely to room temperature within 4hours 30 minutes forming a thick, well stirable white suspension. To the suspension 200 ml water are added and the mixture is stirred for additional 15hours 20 minutes at room temperature. The suspension is filtered and the filter cake is washed twice with 25 ml portions of a mixture of ethanohwater 9: 1 (v/v). The colourless crystals are dried at 60°C in vacuum yielding 26.23g (=91.2% yield). H NMR (400 MHz, DMSO-d6)